Industries We Serve

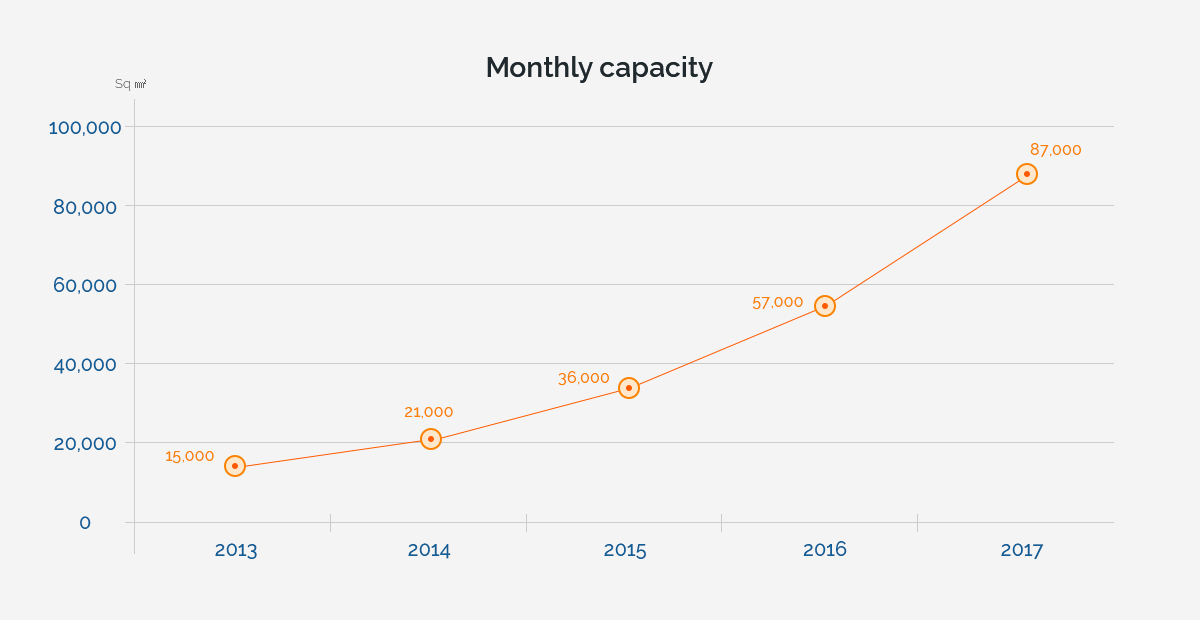

As one of the largest back-end toll processing company in Korea.

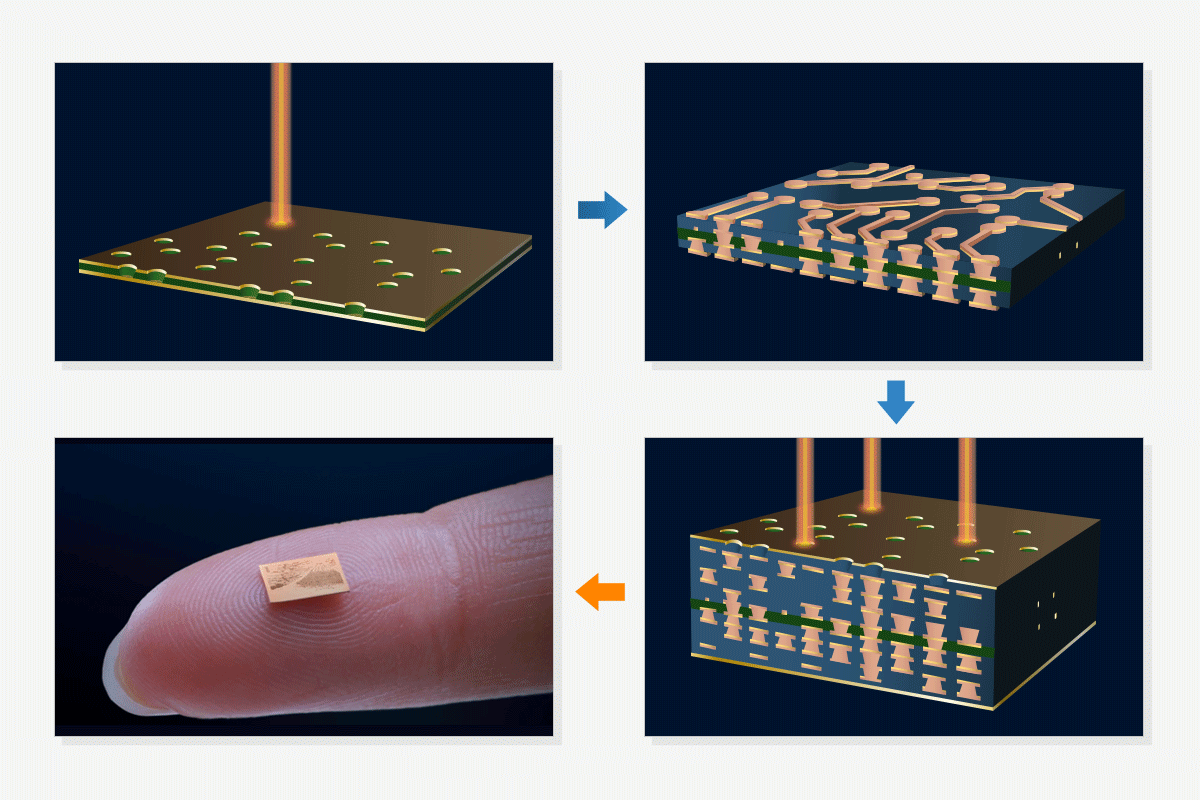

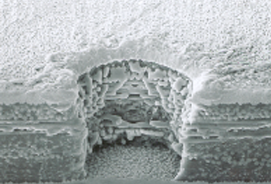

Laser Drilling

If you are looking for a quick and cost-effective way to get small holes drilled in almost any substrate, you have come to the right place.

FuRex is passionate about micro holes. We have some of the most advanced hole drilling capabilities

and are continually developing new processes to drill holes as small as 35㎛.

Our Engineers will work closely with you to fully understand the requirements for your micro holes

(eg. materials, part thickness, desired feature geometries, taper) and recommend a process that will satisfy your production needs.

The biggest change in PCB industry in 2017 was wider application of substrate like(SLP). Compared with traditional HDI(High-Density Interconnection),

the biggest change in the specification of substrate like HDI is the line space/width have miniaturized down to 35㎛ which enables to play on fine pitch.

In line with this change, FuRex has upgraded manufacturing equipment and successfully re-explore production process during 2017.

| Description | ML605GTW_4_H-5350U | ML605GTW_4_P-5350U | ML605GTW_5_P-5350U | |

|---|---|---|---|---|

| Machine Model |  |

|

|

|

Galvano Accuracy  |

± 20㎛ | ± 15㎛ | ± 15㎛ | |

| X Y Table | Working Table Dimensions [mm] |

620 x 560 | ||

| Maximum Transmitting Response [m/min] |

50 | |||

| Resonator | Power[W] | 360 | ||

| Control system Resolving Power | 1㎛ | 0.1㎛ | ||

-

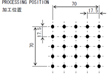

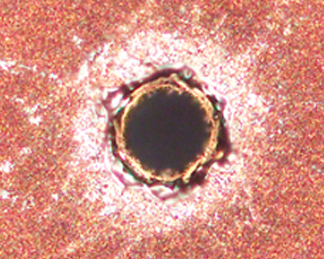

Cu direct Φ35μm

(Black oxide treatment @ 5μm thick) -

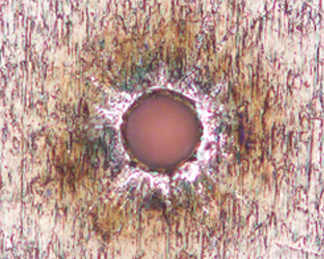

Cu direct Φ35μm

(Etching treatment @ 6μm thick) -

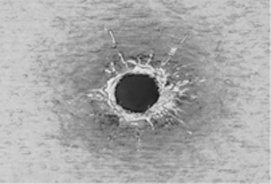

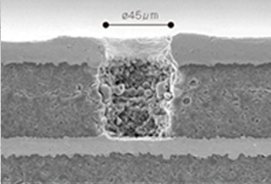

Cu direct Φ35μm

(No treatment @ 2μm thick)

-

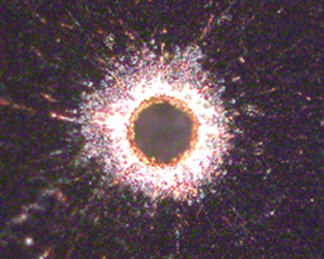

Ave. Φ41.6μm

Roundness 96.2% -

Ave. Φ41.2μm

Roundness 97.8% -

Ave. Φ49.9μm

Roundness 98.1% -

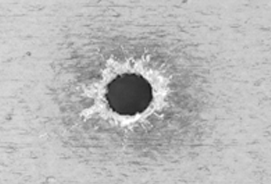

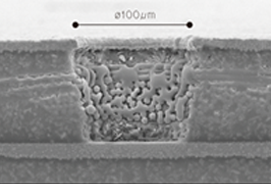

Ave. Φ50.1μm Roundness 97.9%

-

-

-

-

-

-

-

-